PriceList for Seaweed Drying Machine - Corrosion Resistance Salt Spray Test Chamber – Yunboshi

PriceList for Seaweed Drying Machine - Corrosion Resistance Salt Spray Test Chamber – Yunboshi Detail:

- Place of Origin:

-

Jiangsu, China (Mainland)

- Brand Name:

-

YBS

- Model Number:

-

BX-120B

- Power:

-

Electronic

- Usage:

-

Auto Testing Machine, Corrosion Resistant Testing

- Brand:

-

YUNBOSHI

- Model number:

-

BX-120B

- PH:

-

6.5~7.2 3.0~3.2

- Brine Temperature:

-

35°C±1°C

- Test chamber volume:

-

108L,270L,480L,800L

- Temperature Precision:

-

±1°C

- MOQ:

-

1pcs

- material:

-

PVC Planks &PP

- Package:

-

plywood case or honeycomb carton case

- Supply Ability:

- 20 Piece/Pieces per Month salt spray test chamber

- Packaging Details

- salt spray test chamber packing: plywood case or honeycomb carton case

- Port

- Shanghai

- Lead Time :

- within 15 working days

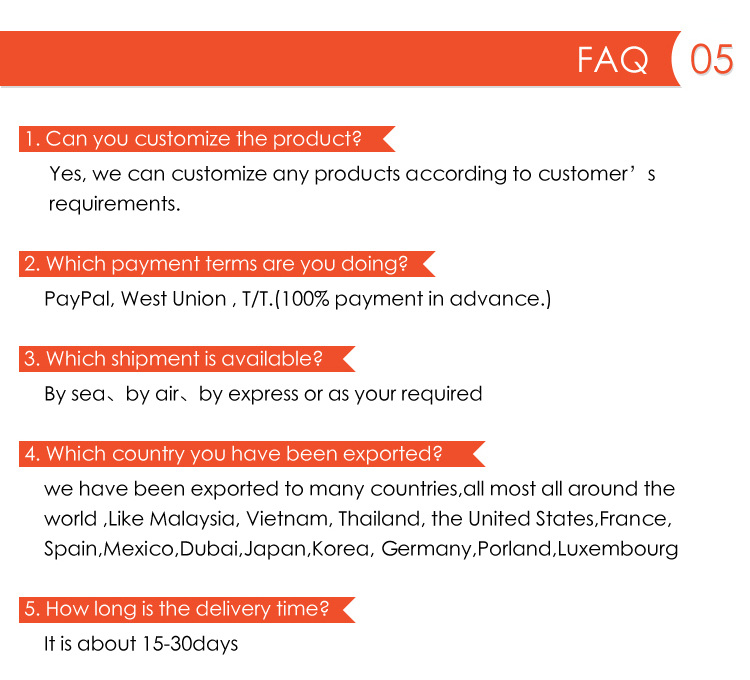

Main Kinds of Test Chamber

Corrosion Resistance Salt Spray Test Chamber

Corrosion Resistance Salt Spray Test Chamber Specification

| Model | YBS-60B | YBS-90B | YBS-120B | YBS-160B |

| Inner size | 60*60*45 | 90*50*60 | 120*50*80 | 160*50*100 |

| Material | Imported PVC&P.P | |||

| Inner temperature | NSS ACSS35±1°C;Corrosion test method50±1°C | |||

| Saturated air barrel temperature | NSS ACSS47±1°C;Corrosion test method63±1°C | |||

| Saline water temperature | 35±1°C | |||

| Memory time | 0~999.9hrs,Power failure memory type,Including buzzer alarm | |||

| Method of spray | Continuous spray;Nozzle 4000hrs no crystallization group, special glass | |||

| Volume of spray | 1.0~2.0 | |||

| PH value | NSS ACSS6.5~7.2;Corrosion test method3.0~3.2 | |||

| Capacity | 108L | 270L | 480L | 800L |

| Voltage | AC220V±10% 1PH 50/60HZ |

|||

Corrosion Resistance Salt Spray Test Chamber Characteristics

Salt spray test chamber method: A:continuous salt spray testing machine

B:Programmable salt spray testing machine.

Use full detection system,fault happan,display light

- Whole PVC board,salt spray testing machine adopts advanced three-dimensional reinforcement technology,strong;

- Salt spray test chamber using automatic/manual water system,automatic/manual supple water when water is short,keep test uninterrupted;

- Precision glass nozzle,spray testing machine ensure no crystallization obstruction when use 4000 hours salt;

- Control instruments are in the same board,easy to operate and clear;

- Attach double overtemperature protection,insufficient water level warning,ensure use safety;

- Digital temperature controller,digital display,PID control,high stability platinum temperature measuring probe,error of 0.3;

- Laboratory use direct steam heating mode,warming faster,standby time shorten salt spray testing machine;

- Spray up with conical disperser,guide the fog,adjust the volume of the fog,even fall mist etc;

- Pressure barrels use Henry's law,heating and humidifying,provide humidity to inner of salt spray testing machine.

Corrosion Resistance Salt Spray Test Chamber Details Shows

Salt spray test chamber meet CNS, ASTM, JIS and ISO standards, salt spray test chamber

is aimed at all kinds of quality of the surface of coating, electroplating, anode processing, materials after the rust-proof,test the corrosion resistance of their products.

salt spray test chamber packing: plywood case or honeycomb carton case.

salt spray test chamber delivery: within 15 working days .

We are a profesional salt spray test chamber manufacturer in China providing different sizes of dehumidification cabinets with various options.

Since we were established in 2004 year we always adhering to the idea of “ profession and quality for establishing a good corporate system. ”

Product detail pictures:

Related Product Guide:

Element’s Warwick Laboratory is open for test innovation | Waterproof Cabinet

This new LED light strip is just like the Philips Hue’s $90 model, but it costs $24 | Humidity Stability Test Chamber

Our enterprise since its inception, constantly regards product good quality as organization life, constantly improve production technology, strengthen merchandise high quality and continuously strengthen enterprise total good quality administration, in strict accordance with all the national standard ISO 9001:2000 for PriceList for Seaweed Drying Machine - Corrosion Resistance Salt Spray Test Chamber – Yunboshi , The product will supply to all over the world, such as: California, Mauritania, New Zealand, Our stock have valued 8 million dollar , you can find the competitive parts within short delivery time. Our company is not only your partner in business, but also our company is your assistant in the coming corporation.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.